Tensile testing is a fundamental engineering process used to assess the properties of materials by applying a controlled tensile (pulling) force to a sample until it reaches the point of failure. This method provides critical data on a material’s strength, ductility, and overall performance under stress, making it an essential tool for evaluating the structural integrity of various components. The results obtained during tensile testing are particularly valuable for assessing the reliability and durability of joints, as they help identify any weaknesses or inconsistencies that could compromise long-term performance.

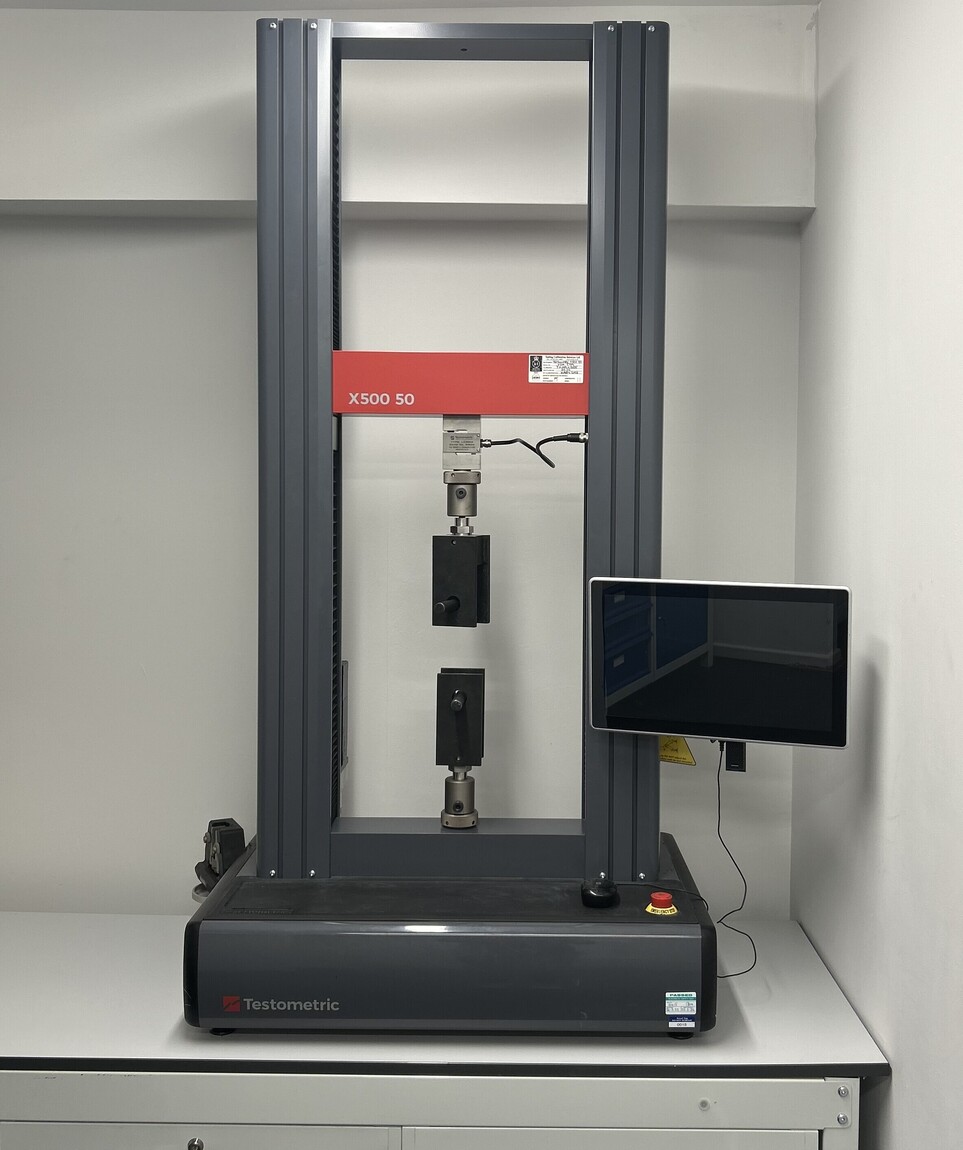

At our specialised testing facility, we offer professional tensile testing services specifically focused on evaluating butt fusion and electro-fusion joints. Our lab is equipped with advanced testing equipment and operated by experienced technicians who ensure that each test is carried out to the highest industry standards. We meticulously analyse each joint to determine its ductility.

Upon completion of testing, we provide comprehensive, easy-to-understand reports that detail the findings. These reports include quantitative results, graphical data, and expert interpretation. Whether for failure investigation or routine quality assurance, our tensile testing services play a vital role in supporting the safety, reliability, and performance of your pipeline or structural systems.